Moving from "Maker" prototyping to Final product

Given the plethora of open source hardware and software available to developers, it's relatively easy to put something quickly together to do a particular job. But taking an initial breadboarded prototype to a commercialisable product is a more challenging task

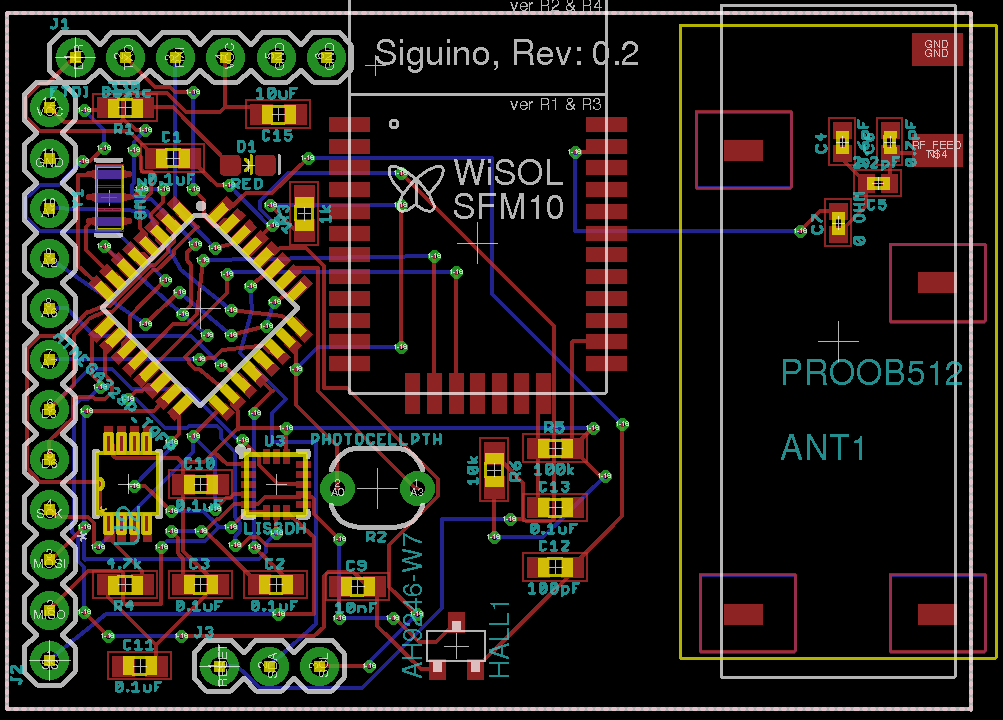

Here we see an example of the general path taken, from basic breadboard (lots of wires), to a tighter breadboarding, then a minimal stripboard and finally a custom designed and routed PCB. I wrote an article about the full end-to-end project here on CodeProject

Results

The final design can then be printed at a PCB fabrication house and hand assembled (in small numbers, for testing mainly) or once tested, sent to be manufactured. In this case I designed a generic sensors board based on an Arduino Pro Mini, with both a range of different sensors as well as SigFox communication chip built-in (along with an OnBoard antenna) for use with batteries in ultra low power sensor applications. These images are of the prototype stages of the Siguino project